ApexPashmina, often referred to as the “soft gold” of the Himalayas, is renowned for its unparalleled softness, warmth, and elegance. At ApexPashmina, we honor the age-old traditions of Pashmina weaving, bringing to life exquisite scarves and shawls that are a testament to the rich heritage and meticulous craftsmanship of the Kashmir region.

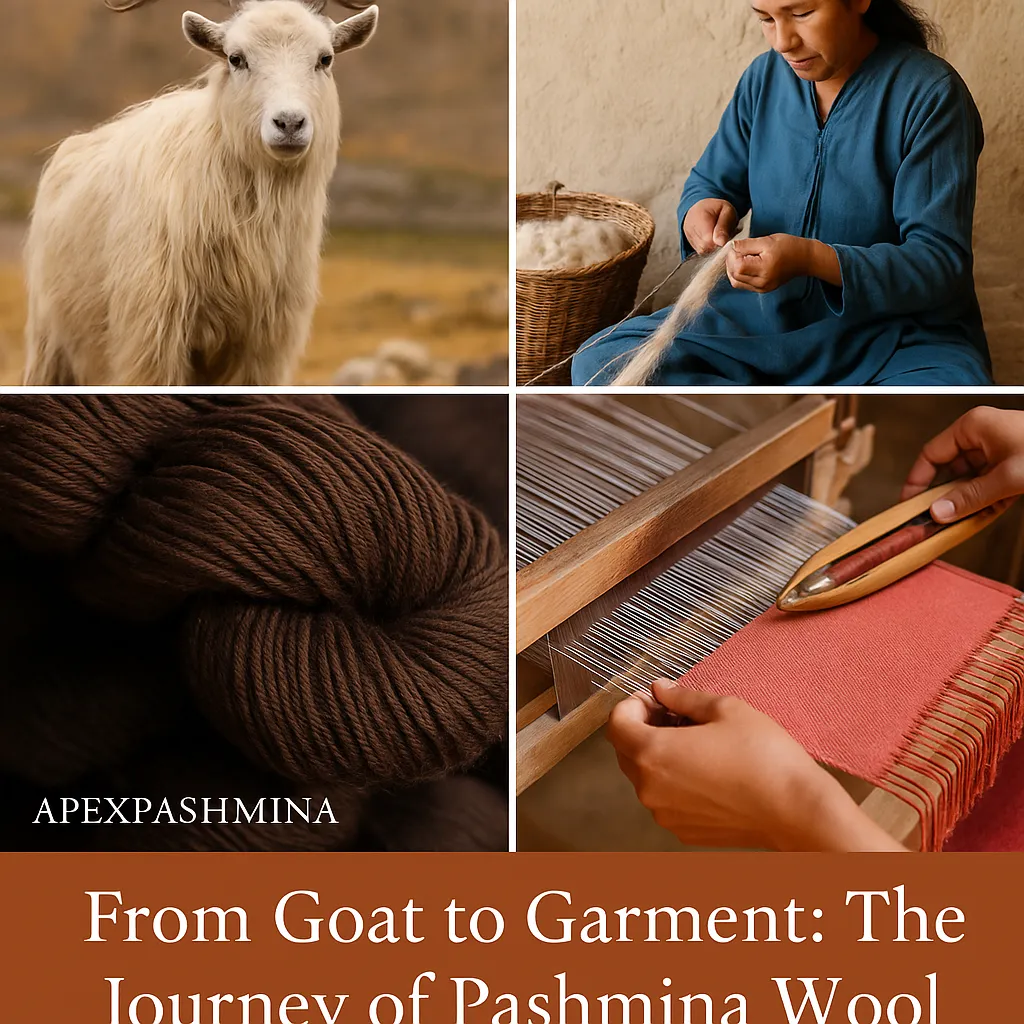

In this comprehensive guide, we delve into the traditional techniques employed in crafting Pashmina products, offering a step-by-step journey from the raw fiber to the finished masterpiece.

1. The Origin: Changthangi Goats of Ladakh

The Changthangi Goat

The journey begins in the high-altitude regions of Ladakh, where the Changthangi goats, also known as Pashmina goats, thrive. These goats develop a fine undercoat to withstand the harsh winters, and it is this undercoat that yields the prized Pashmina wool.

The Changpa Nomads

The Changpa nomads, indigenous to the Changthang plateau, have been rearing these goats for generations. Their traditional knowledge and sustainable herding practices play a crucial role in maintaining the quality of Pashmina wool.

2. Harvesting the Wool

Combing the Undercoat

During the spring molting season, herders gently comb the goats to collect the soft undercoat fibers. This process is done with utmost care to ensure the well-being of the animals and the quality of the wool.

Yield and Quality

Each goat produces only about 80 grams of Pashmina wool annually, making the material exceptionally rare and valuable. The collected fibers are then sorted to separate the finest quality wool.

3. Cleaning and Sorting

Once collected, the raw Pashmina wool undergoes a meticulous cleaning process to remove impurities. Skilled artisans then sort the fibers based on fineness and length, ensuring only the highest quality wool is used for weaving.

4. Spinning the Yarn

The cleaned fibers are hand-spun into yarn using traditional spinning wheels, known locally as “charkha.” This delicate process requires immense skill to produce uniform and fine threads, which are essential for the softness and durability of the final product.

5. Dyeing the Yarn

At ApexPashmina, we embrace both natural and eco-friendly dyes to impart vibrant hues to our products. The dyeing process is carefully controlled to ensure colorfastness and to maintain the integrity of the delicate fibers.

6. Preparing the Loom

Setting the Warp

The warp threads are meticulously arranged on traditional wooden looms. This setup determines the length and width of the fabric and requires precision to ensure even tension and alignment.

The Weaving Process

Weaving is performed entirely by hand, with artisans interlacing the weft threads through the warp to create the fabric. This labor-intensive process can take several days to complete a single piece, depending on the complexity of the design.

7. Finishing Touches

Washing and Softening

The woven products are gently washed to remove any residual impurities and to soften the fabric. Traditional methods involve using natural soaps and drying the items in the shade to preserve their luster.

Embellishments

Some products may feature intricate hand-embroidery or fringe detailing, adding a unique touch to each piece. These embellishments are crafted by skilled artisans, further enhancing the beauty of the item.

8. Quality Control

Each product undergoes a rigorous quality control process to ensure it meets ApexPashmina’s standards of excellence. This includes checking for uniformity in weave, color consistency, and overall finish.

9. Packaging and Presentation

The final products are carefully folded and packaged, ready to be delivered to customers worldwide. Our packaging reflects the elegance of the product, making it suitable for gifting or personal indulgence.

Conclusion

Crafting a Pashmina product is a labor of love, intertwining tradition, skill, and artistry. At ApexPashmina, we are committed to preserving these age-old techniques, ensuring that each item we produce is not just an accessory but a piece of heritage.